Clean Better With Cold - See How

Dry Ice Blast Cleaning

Dry ice Blasting. Clean better with ice.

Get light or deep, cleaning, using dry ice blasting.

Dry ice blasting uses small pieces of dry ice the size of rice that “explode” against the contaminant, causing it to shrink and lose its adhesion. Dry ice is very cold -109°F or -78°C.

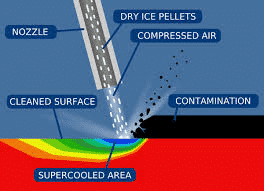

The dry ice pieces shoot out of a jet nozzle with compressed air. The nozzle’s unique shape can cause the particles to accelerate faster than the speed of sound before hitting the surface to be cleaned. (see energies-12-04787 for analysis)

Other systems shave a dry ice block for softer blast cleaning material.

The dry ice is softer than sand or glass beads, so it does not spoil the substrata. It works like sandblasting or high-pressure water or steam blasting, but with different results – often better.

The combination of kinetic, thermal, and sublimation energy produces unparalleled results. The super cold temperature of the dry ice blasting against the material to be removed causes it to shrink and lose adhesion from its subsurface. Additionally, some dry ice penetrates through the contaminated material and contacts the warmer original surface, causing the dry ice to turn into a gas, expanding under the harmful material and speeding its removal.

Rust, paint, oil, grease, asphalt, tar, decals, soot, dirt, ink, resins, jet exhaust tars, and adhesives are materials removed by this procedure. Only the removed material must be disposed of, as the dry ice sublimes into the atmosphere.

Dry ice blasting does not create secondary waste or chemical residues and is

non-abrasive

non-conductive,

non-flammable,

and non-toxic.

It reduces personal contact with harmful chemicals and is an environmentally friendly cleaning method approved by the FDA, EPA, and USDA. In addition, dry ice blasting can replace environmentally dangerous solvents safely and is less costly.

Before repainting old corroded flaking surfaces, dry ice blast cleaning will clean and prepare the component for its new coating. The part is immediately available to paint – no waiting for drying or dangerous solvents to be removed.

Use dry ice blast cleaning to restore fire-damaged buildings and rooms – successfully removing the char and smoke damage to wood and other materials.

Many in-house uses for maintaining or cleaning equipment with dry ice blast cleaning result in reduced downtime and higher annual production. The best solution may be an experienced professional contractor who can clean your equipment safely and quickly.

Start a new business or let your existing business meet more of your customer’s needs with dry ice blast cleaning.

Before purchasing dry ice blast cleaning equipment that may cost anywhere from $15,000 to $50,000, consider renting dry ice blasting equipment. Also, some companies offer training for their equipment.

Find all this and more through the many professional companies presenting their equipment and services on this website.

Include your dry ice blast cleaning services or equipment for new customer contacts.

Additional Supporters:

Enjoy custom research writing services provided by professional academic writers from SmartWritingService.com.

Interesting android app for kids showing experiments with dryice science experiments with ice apk

Professional Companies Offering Services

RENT-LEASE-SALES

World’s Largest Rental Inventory

Stephen Telofski, Manager

732-447-5759

At Enviro-Blast, we offer full-service dry ice blasting to a number of different industries.

586 756-4570

Warren, MI 48091

We are an eco-friendly industrial services company that specializes in cleaning and maintaining heavy industrial equipment and machinery

China Professional Dry Ice Blaster Manufacturer

Sinocean Suzhou Ltd.

Jinfeng Center, Gaoxin District, China

https://www.co2industries.com/

Email:

Whatsapp: +86 156 0154 8720

Premier Dry Ice Blasting company offering Consulting, Services, and Products.

- Dry Ice Blasting Unit Rentals

- Dry Ice Blasting Unit Sales

- Dry Ice Equipment Sales

- Industrial Cleaning Project Management

- Dry Ice Sales and Brokering

- Start-Up Business Consulting

Interstate Carbonicc Enterprises

844-423-4212

Email Inquiry To:

www.InterstateCarbonic.com

Repair, refurbish, or replace all Phoenix equipment.

Repair, refurbish, or replace all Phoenix equipment.

Dry ice blasting contract services, machine sales, and rentals. Serving throughout the US. Call 803-831-1746

Visit www.dryiceblastingusa.com/

Professional Companies Offering Services

Main Office

100 Cloniger Drive

Thomasville

North Carolina, 27360

Tel (336) 476-9274 Ex 2

E-Mail:

Web dunnservice.com